Enhancing Quality Control with Automated Optical Inspection: A Maker-ray Solution

In today’s competitive manufacturing landscape, ensuring product quality is paramount. To achieve consistent quality control, industries are turning to advanced technologies like Automated Optical Inspection (AOI). This article explores the significance of AOI and introduces Maker-ray, a leading brand that revolutionizes AOI solutions for enhanced quality assurance.

Understanding Automated Optical Inspection (AOI)

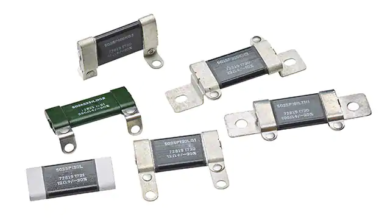

Automated Optical Inspection (AOI) is an advanced technology used for inspecting manufactured products such as printed circuit boards (PCBs), electronic components, and assemblies. It leverages high-resolution cameras, sophisticated algorithms, and machine learning to detect defects, inconsistencies, or errors in the production process. By automating the inspection procedure, AOI improves accuracy, saves time, and reduces human error.

The Benefits of Implementing AOI in Manufacturing Processes Implementing

AOI brings numerous advantages to manufacturing processes. Firstly, it enhances defect detection accuracy, leaving no room for human oversight. AOI systems can identify issues that may go unnoticed during manual inspections, ensuring higher product quality. Secondly, AOI significantly reduces inspection time, enabling faster production cycles and quicker time-to-market. Moreover, AOI helps optimize the overall manufacturing process by identifying areas prone to errors, allowing manufacturers to make necessary adjustments promptly.

Introducing Maker-ray: Revolutionizing AOI for Enhanced Quality Assurance Maker-ray is a renowned brand at the forefront of AOI solutions. With its cutting-edge technology, Maker-ray has transformed quality assurance in manufacturing. Their AOI systems are equipped with advanced features such as intelligent algorithms, real-time data analysis, and customizable inspection parameters. Maker-ray’s solutions offer seamless integration into existing production lines, ensuring smooth operations without disrupting workflow. By combining speed, precision, and reliability, Maker-ray enables manufacturers to achieve high-quality products consistently.

Conclusion

Transforming Quality Control with Maker-ray AOI In conclusion, Automated Optical Inspection (AOI) plays a vital role in modern manufacturing processes. Its ability to detect defects accurately and automate inspections brings numerous benefits to industries. Maker-ray, with its innovative AOI solutions, takes quality control to the next level. By harnessing the power of Maker-ray’s technology, manufacturers can achieve enhanced quality assurance, improved productivity, and increased customer satisfaction.